The Benefits of Using casing and Tubing coupling in Oil and gas drilling Operations

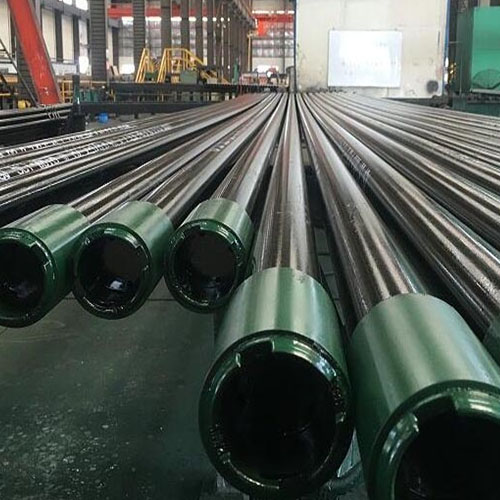

Casing and tubing coupling are essential components of oil and gas drilling operations. They are used to connect sections of casing and tubing, allowing for the safe and efficient transfer of oil and gas from the wellbore to the surface. Casing and tubing coupling provide a number of benefits that make them invaluable in oil and gas drilling operations.

oil Pipe,oil pipe joint, oil pipelines company china, oil pipe from tank to boiler, oil pipe insulation, oil pipeline construction cost per km, oil pipe for sale near me, oil pipeline contractor in China, oil pipe cutter, oil pipe leak, oil pipe size chart, oil pipeline construction, oil pipeline cleaning, oil pipe fence, oil pipeline, oil pipe, oil pipeline company, oil pipe welder,oil pipeline,oil pipe insulation,oil pipeline contractor in China,oil pipe size chart,oil pipeline company,oil pipe from tank to boiler,oil pipe|oil pipe cutter,oil pipe leak,oil pipe for sale near me,oil pipeline inspection robot,oil pipeline construction,oil pipe welder,oil pipeline cleaning,tubing near me,tubing connector,tubing pipe,casing pipe Chinese good factory,casing pipe China good wholesaler,oil tube Wholesale-price high-quality high-grade Chinese

First, casing and tubing coupling are designed to provide a secure connection between sections of casing and tubing. This ensures that the wellbore remains sealed and that the oil and gas are safely contained within the wellbore. Additionally, the coupling helps to reduce the risk of leaks and other problems that can occur when sections of casing and tubing are not properly connected.

Second, casing and tubing coupling are designed to be highly durable and reliable. This ensures that the connection between sections of casing and tubing remains secure and that the oil and gas are safely contained within the wellbore. Additionally, the coupling helps to reduce the risk of corrosion and other problems that can occur when sections of casing and tubing are not properly connected.

| Labels | Outside diameter (d/mm) |

T&C (kg/m) |

Wall thickness (t/mm) |

Type of end-finish | |||||||

| 1 | 2 | J55/ K55 | M65 | L80/ R95 | N80-1/Q | C90/ T95 | P110 | Q125 | |||

| 4-1/2 | 9.50 | 114.30 | 14.14 | 5.21 | PS | PS | – | – | – | – | – |

| 10.50 | 114.30 | 15.63 | 5.69 | PSB | PSB | – | – | – | – | – | |

| 11.60 | 114.30 | 17.26 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 13.50 | 114.30 | 20.09 | 7.37 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 15.10 | 114.30 | 22.47 | 8.56 | – | – | – | – | – | PLB | PLB | |

| 5 | 11.50 | 127.00 | 17.11 | 5.59 | PS | PS | – | – | – | – | – |

| 13.00 | 127.00 | 19.35 | 6.43 | PSLB | PSLB | – | – | – | – | – | |

| 15.00 | 127.00 | 22.32 | 7.52 | PSLB | PLB | SLB | PLB | PLB | PLB | ||

| 18.00 | 127.00 | 26.79 | 9.19 | – | PLB | SLB | PLB | PLB | PLB | PLB | |

| 21.40 | 127.00 | 31.85 | 11.10 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.20 | 127.00 | 34.53 | 12.14 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 24.10 | 127.00 | 35.87 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 5-1/2 | 14.00 | 139.70 | 20.83 | 6.20 | PS | PS | – | – | – | – | – |

| 15.50 | 139.70 | 23.07 | 6.98 | PSLB | PSLB | – | – | – | – | – | |

| 17.00 | 139.70 | 25.30 | 7.72 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 20.00 | 139.70 | 29.76 | 9.17 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 23.00 | 139.70 | 34.23 | 10.54 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.80 | 139.70 | 39.88 | 12.70 | – | – | – | – | P | – | – | |

| 29.70 | 139.70 | 44.20 | 14.27 | – | – | – | – | P | – | – | |

| 32.60 | 139.70 | 48.52 | 15.88 | – | – | – | – | P | – | – | |

| 35.30 | 139.70 | 52.53 | 17.45 | – | – | – | – | P | – | – | |

| 38.00 | 139.70 | 56.55 | 19.05 | – | – | – | – | P | – | – | |

| 40.50 | 139.70 | 60.27 | 20.62 | – | – | – | – | P | – | – | |

| 43.10 | 139.70 | 64.14 | 22.22 | – | – | – | – | P | – | – | |

| 6-5/8 | 20.00 | 168.28 | 29.76 | 7.32 | PSLB | PSLB | – | – | – | – | – |

| 24.00 | 168.28 | 35.72 | 8.94 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 28.00 | 168.28 | 41.67 | 10.59 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 168.28 | 47.62 | 12.06 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 7 | 17.00 | 177.80 | 25.30 | 5.87 | – | – | – | – | – | – | – |

| 20.00 | 177.80 | 29.76 | 6.91 | PS | PS | – | – | – | – | – | |

| 23.00 | 177.80 | 34.23 | 8.05 | PSLB | PLB | PLB | PLB | PLB | – | – | |

| 26.00 | 177.80 | 38.69 | 9.19 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 29.00 | 177.80 | 43.16 | 10.36 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 177.80 | 47.62 | 11.51 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 35.00 | 177.80 | 52.09 | 12.65 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 38.00 | 177.80 | 56.55 | 13.72 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.70 | 177.80 | 63.55 | 15.88 | – | – | – | – | P | – | – | |

| 46.40 | 177.80 | 69.05 | 17.45 | – | – | – | – | P | – | – | |

| 50.10 | 177.80 | 74.56 | 19.05 | – | – | – | – | P | – | – | |

| 53.60 | 177.80 | 79.77 | 20.62 | – | – | – | – | P | – | – | |

| 57.10 | 177.80 | 84.98 | 22.22 | – | – | – | – | P | – | – | |

| 7-5/8 | 24.00 | 193.68 | 35.72 | 7.62 | – | – | – | – | – | – | |

| 26.40 | 193.68 | 39.29 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 29.70 | 193.68 | 44.20 | 9.52 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 33.70 | 193.68 | 50.15 | 10.92 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 39.00 | 193.68 | 58.04 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.80 | 193.68 | 63.69 | 14.27 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 45.30 | 193.68 | 67.42 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 47.10 | 193.68 | 70.09 | 15.88 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 51.20 | 193.68 | 76.20 | 17.45 | – | – | – | – | P | – | – | |

| 55.30 | 193.68 | 82.30 | 19.05 | – | – | – | – | P | – | – | |

| 7-3/4 | 46.10 | 196.85 | 68.61 | 15.11 | – | – | P | P | P | P | P |

| 8-5/8 | 24.00 | 219.08 | 35.72 | 6.71 | PS | PS | – | – | – | – | – |

| 28.00 | 219.08 | 41.67 | 7.72 | PS | – | – | – | – | – | ||

| 32.00 | 219.08 | 47.62 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 36.00 | 219.08 | 53.58 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | PLB | – | |

| 40.00 | 219.08 | 59.53 | 11.43 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 44.00 | 219.08 | 65.48 | 12.70 | – | – | PLB | PLB | PLB | PLB | – | |

| 49.00 | 219.08 | 72.92 | 14.15 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 9-5/8 | 32.30 | 244.48 | 48.07 | 7.92 | – | – | – | – | – | – | – |

| 36.00 | 244.48 | 53.58 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 40.00 | 244.48 | 59.53 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 43.50 | 244.48 | 64.74 | 11.05 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 47.00 | 244.48 | 69.95 | 11.99 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 53.50 | 244.48 | 79.62 | 13.84 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 58.40 | 244.48 | 86.91 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 59.40 | 244.48 | 88.40 | 15.47 | – | – | – | – | P | – | – | |

| 64.90 | 244.48 | 96.58 | 17.07 | – | – | – | – | P | – | – | |

| 70.30 | 244.48 | 104.62 | 18.64 | – | – | – | – | P | – | – | |

| 75.60 | 244.48 | 112.51 | 20.24 | – | – | – | – | P | – | – | |

| 10-3/4 | 32.75 | 273.05 | 48.74 | 7.09 | – | – | – | – | – | – | – |

| 40.50 | 273.05 | 60.27 | 8.89 | PSB | PSB | – | – | – | – | – | |

| 45.50 | 273.05 | 67.71 | 10.16 | PSB | PSB | – | – | – | – | – | |

| 51.00 | 273.05 | 75.90 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 55.50 | 273.05 | 82.60 | 12.57 | – | PSB | PSB | PSB | PSB | PSB | – | |

| 60.70 | 273.05 | 90.33 | 13.84 | – | – | – | – | PSB | PSB | PSB | |

| 65.70 | 273.05 | 97.77 | 15.11 | – | – | – | – | PSB | PSB | PSB | |

| 73.20 | 273.05 | 108.94 | 17.07 | – | – | – | – | P | – | – | |

| 79.20 | 273.05 | 117.87 | 18.64 | – | – | – | – | P | – | – | |

| 85.30 | 273.05 | 126.94 | 20.24 | – | – | – | – | P | – | – | |

| 11-3/4 | 42.00 | 298.45 | 62.50 | 8.46 | – | – | – | – | – | – | – |

| 47.00 | 298.45 | 69.95 | 9.53 | PSB | PSB | – | – | – | – | – | |

| 54.00 | 298.45 | 80.36 | 11.05 | PSB | PSB | – | – | – | – | – | |

| 60.00 | 298.45 | 89.29 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | PSB | |

| 65.00 | 298.45 | 96.73 | 13.56 | – | – | P | P | P | P | P | |

| 71.00 | 298.45 | 105.66 | 14.78 | – | – | P | P | P | P | P | |

| 13-3/8 | 48.00 | 339.72 | 71.43 | 8.38 | – | – | – | – | – | – | – |

| 54.50 | 339.72 | 81.11 | 9.65 | PSB | PSB | – | – | – | – | – | |

| 61.00 | 339.72 | 90.78 | 10.92 | PSB | PSB | – | – | – | – | – | |

| 68.00 | 339.72 | 101.20 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 72.00 | 339.72 | 107.15 | 13.06 | – | – | PSB | PSB | PSB | PSB | PSB | |

| 16 | 65.00 | 406.40 | 96.73 | 9.53 | – | – | – | – | – | – | – |

| 75.00 | 406.40 | 111.62 | 11.13 | PSB | PSB | – | – | – | – | – | |

| 84.00 | 406.40 | 125.01 | 12.57 | PSB | PSB | – | – | – | – | – | |

| 109.00 | 406.40 | 162.21 | 16.66 | P | – | P | P | – | P | P | |

| 18-5/8 | 87.50 | 473.08 | 130.22 | 11.05 | PSB | PSB | – | – | – | – | – |

| 20 | 94.00 | 508.00 | 139.89 | 11.13 | PSLB | PSLB | – | – | – | – | – |

| 106.50 | 508.00 | 158.49 | 12.70 | PSLB | PSLB | – | – | – | – | – | |

| 133.00 | 508.00 | 197.93 | 16.13 | PSLB | – | – | – | – | – | – | |

Third, casing and tubing coupling are designed to be easy to install and maintain. This makes them ideal for use in oil and gas drilling operations, as they can be quickly and easily installed and maintained. Additionally, the coupling helps to reduce the risk of downtime and other problems that can occur when sections of casing and tubing are not properly connected.

Finally, casing and tubing coupling are designed to be cost-effective. This makes them an ideal choice for oil and gas drilling operations, as they can help to reduce the overall cost of the operation. Additionally, the coupling helps to reduce the risk of costly repairs and other problems that can occur when sections of casing and tubing are not properly connected.

In conclusion, casing and tubing coupling are essential components of oil and gas drilling operations. They provide a secure connection between sections of casing and tubing, ensuring that the wellbore remains sealed and that the oil and gas are safely contained within the wellbore. Additionally, they are highly durable and reliable, easy to install and maintain, and cost-effective, making them an ideal choice for oil and gas drilling operations.